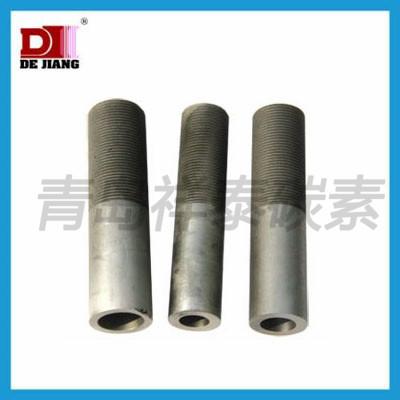

graphite mould for copper casting

Model No.︰-

Brand Name︰dejiang

Country of Origin︰-

Unit Price︰US $ 5 / pc

Minimum Order︰100 pc

Product Description

Used in furnaces because of graphite's low heat sensitivity

Used in the production of fluxing tubes used in the metal manufacturing industry

Other industries using graphite tubes include chemical and scientific industry

Hard Alloys, Graphite Mold, Diamond Aiguille, Saw Sinter Film, semiconductor Monocrystal Graphite Mold, Continuous Casting, Casting Steel, Alloys casting, Metals Casting, Graphite for Ray-cable, Graphite for Mid or Mini-type Rocket, Crucibles

Bulk density (g/m3) |

Max grain size (mm) |

Ash (%) |

Electrical Resistivity (μ Ω m) |

Compressive Strength (MPa) |

1.60 |

0.8-2 |

≤0.5 |

≤10 |

≥20 |

1.68 |

≤8 |

≥22 |

||

1.72 |

≤7.5 |

≥25 |

||

1.75 |

≤7 |

≥28 |

Specifications |

Unit |

High-graphitic |

Graphitic |

graphitized |

||

30% |

50% |

80% |

||||

Real Density |

g/cm3 |

≥1.94 |

≥1.98 |

≥2.00 |

≥2.08 |

≥2.20 |

Bulk Density |

g/cm3 |

≥1.56 |

≥1.60 |

≥1.62 |

≥1.65 |

≥1.56 |

Special Electrical Resistivity |

μΩm |

≤35 |

≤29 |

≤25 |

≤21 |

≤11-13 |

Ash Content |

% |

≤5.0 |

≤4.5 |

≤3.0 |

≤2.0 |

≤0.4 |

Compressive Strength |

MPa |

≥25 |

≥24 |

≥22 |

≥21 |

≥20 |

Bending Strength |

MPa |

≥7.0 |

≥7.0 |

≥7.0 |

≥7.5 |

≥6.0 |

Modulus of Elasticity |

GPa |

≤7.0 |

≤7.0 |

≤7.0 |

≤6.5 |

≤6.0 |

Coefficient of Thermal Expansion |

10-6/k |

≤4.0 |

≤4.0 |

≤4.0 |

≤4.0 |

≤2.0 |

Sodium Expansion |

% |

≤0.8 |

≤0.7 |

≤0.6 |

≤0.5 |

≤0.5 |

Porosity |

% |

≤20 |

≤19 |

≤19 |

≤21 |

≤25 |

Thermal Conductivity |

W/mk |

≥8 |

≥12 |

≥12 |

≥15 |

≥100-130 |

Main Raw Materials |

Imported or domestic graphite specialties, medium grain size graphite, graphite blocks, graphite electrode. |

|||||

Processing Treatment |

Oxidation retardant impregnation can be available. |

|||||

Machining |

Materials can be machined to finished products as per given drawings or samples. |

|||||

Typical Applications |

Instruments, copper and aluminium continuous casting, electronic industry, non-ferrous metal industry etc. |

|||||

Payment Terms︰ T/T

Product Image